Stratification

Hull lamination: how to laminate your boat?

Do you own a boat? Would you like to laminate it? Read on to find out how to successfully laminate your boat.

What is stratification?

Boat hull lamination increases the strength and lifespan of your boat's hull. If you use your boat regularly, it may be exposed to a variety of shocks and UV rays.

It's important to know that laminating involves a number of different stages. It's a delicate process that requires discipline to achieve a positive result.

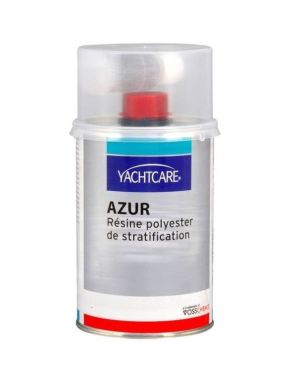

One of the elements to be used for your laminating is thermosetting resin. It has a special feature: it hardens at high temperatures. It's this resin that makes laminating such a delicate operation, because once you've applied the resin to your boat's hull with its hardening effect, you need to be really sure you've done it right, because once the resin has hardened, you can't do it again.

What are the steps involved in perfect laminating?

-

Step 1: Prepare the shell

In this step, you must prepare the hull for lamination, i. e. you must sand it to make it smooth enough.

Once the hull is smooth enough, you'll need to clean it thoroughly with acetone solvent.

-

Step 2: Materials, equipment and products

-

Equipment

As mentioned above, layering is a fairly delicate process, so make sure you have all the necessary equipment around you so you can carry out the steps at the right time and be sure of a satisfactory result.

At this stage, be sure to prepare the right amount of fabric, resin and hardener for your specific needs.

-

Equipment

You'll need safety equipment, especially since, as you know, you'll be handling chemicals during this operation:

-

Coveralls

-

Safety goggles

-

Gloves

-

Mask

-

Product

How to choose the right product for laminating?

When it comes to resin, it's best to work with epoxy resin, as it offers advantages such as water resistance and excellent adhesion.

However, it is advisable to use it at a temperature between 20 and 25 degrees. Perfect results, as it's a little difficult to work with

-

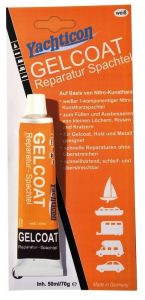

Step 3: Resin application

Start by applying the resin to the hull so that it covers it completely.

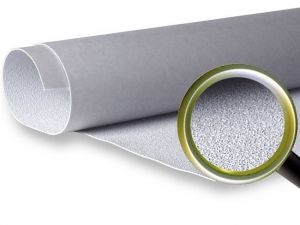

Next, you'll need to apply a first layer of fabric to which you'll apply the resin.

Finally, you can repeat the operation once more, or as many times as you like, until you have the thickness you want.

A few tips

-

Make sure you're working at the right temperature

-

Make sure you're in ideal conditions for the hull to dry.

-

Make sure you choose the right chemicals for your temperature. For example, if you're working with temperatures that aren't too high, be sure to choose a fast hardener.

NB: For successful lay-up, we recommend working in a room with a dry atmosphere.

In conclusion, remember that this is a very delicate process. Be rigorous and diligent in following each step, and you'll succeed in laminating your hull.